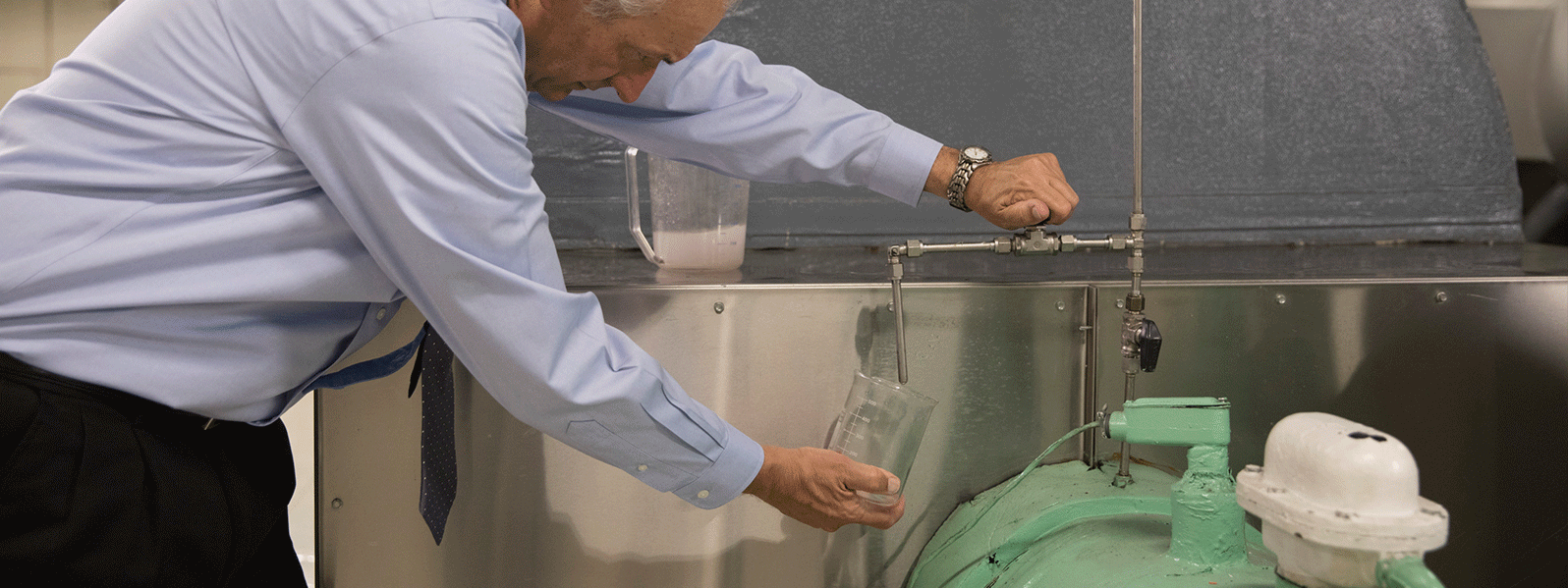

Fall is a busy season for our water quality engineers. They’re helping facility managers prepare open-loop water systems for winter and low-flow season. Part of those winter preparations involves a thorough cooling tower cleaning or disinfection. Read on to learn why that’s important, as well as what to expect.

Fall is a busy season for our water quality engineers. They’re helping facility managers prepare open-loop water systems for winter and low-flow season. Part of those winter preparations involves a thorough cooling tower cleaning or disinfection. Read on to learn why that’s important, as well as what to expect.

Why Clean Or Disinfect Your Cooling Tower?

Like all of the equipment in your facility, cooling towers need regular care and maintenance. Neglecting this hard-working part of your water system can lead to:

- Untimely equipment downtime

- Legionella source risk

- Plugged up equipment

- Treatment program issues in subsequent years

Expensive equipment repairs are bad enough, but here are three more important reasons to keep your towers cleaned and disinfected:

1. Personal Safety

The biofilm, algae, and debris that collects in your cooling towers form a hotbed for bacteria growth – including Legionella. A thorough cleaning can help your biocide work to control pathogen growth and prevent outbreaks.

According to Darius Barkauskas, Technical Director at HOH, Legionella outbreaks can happen to anyone:

“We were recently called to a facility that had a Legionella outbreak and unfortunately, someone died as a result. While in this case, the Legionella growth was traced to the domestic hot water system, it could easily occur in a cooling tower as well – most Legionella outbreaks start there.”

2. Increased efficiency

Keeping your cooling towers clean will help them operate at maximum efficiency levels. You’ll save chemical costs, energy, water usage, and maintenance dollars year-over-year.

3. Extended lifespan

Everything works harder when it has to compensate for dirt/dust/debris clogging the system. Over time, you’ll stress out your equipment and end up spending additional maintenance dollars to repair or replace components or possibly even your whole system.

What’s The Difference Between Cooling Tower Cleaning and Disinfection?

Disinfection means adding in chemicals or additives to remediate biological activity.

Disinfection means adding in chemicals or additives to remediate biological activity.

HOH’s proven process for disinfecting cooling towers involves treating the water chemically, and then circulating, draining, and re-testing until there is no evidence of biofilm.

It’s important to follow industry best practices for cooling tower cleaning and disinfection says Barkauskas:

“Our disinfection process is based on recommendations from industry organization Association of Water Technologies (AWT) as well as CDC guidelines and of course ANSI/ASHRAE Standard 188.”

Cooling Tower Cleanings

Cleaning a cooling tower can be accomplished by either mechanical cleaning or chemical cleaning.

Chemical cleaning comes in three forms:

- Acid cleaning, for scale and rust removal

- Dispersant cleaning, to loosen deposits and strip biofilm

- Disinfection, for bacteria control and Legionella risk-abatement

Mechanical cleaning involves power washing with professional equipment.

Before anyone can clean your towers, they’ll have to be inspected and cleared of any debris that might be clogging them.

“It’s amazing what we’ve found in people’s towers,” says Barkauskas, “Birds. Garbage. One tower had so much dirt in it that prairie grass was able to grow. We had to pull a big chunk of grass out before we could do the cleaning.”

When Should I Clean vs. Disinfect?

At HOH, we recommend disinfection for any cooling tower displaying persistently high bacteria counts or positive Legionella tests.

As for when it’s time for a cleaning, we recommend it when you have visual evidence of moss or algae growing, scaling present, or if you have areas of the cooling tower with intermittent water flow.

“In some industries, people are starting to do more preventative maintenance that involves disinfection. Hospitals and food processing plants will do more disinfection in their facilities than say a manufacturing plant. It just depends on your needs,” says Barkauskas.

The goal should be to start clean and stay clean.

“You’ll get better chemistry, better heat transfer, and mitigate risk and liability.”

Costs for Cooling Tower Cleaning and Disinfection

Typically cooling tower cleaning packages will cost you somewhere between $5,000 – $15,000.

Costs can fluctuate based on:

- Amount of remediation necessary

- Size and complexity of systems

Just make sure that part of getting your estimate and negotiating your job involves a discussion on what your definition of clean is.

Barkauskas advises: “The provider and customer need to be on the same page on what clean will be so there are no surprises later. We make sure to explain to our customers what we’ll be doing and what their towers will look like when we’re done. We even take before and after photos.”

How Long Will It Take To Clean My Cooling Tower?

A small-to-medium-sized system usually takes our team one whole day. It’s typically not longer than two full 8-hour days of work for us. We send a minimum of one to two technicians and our account managers are involved to manage the project and provide customer communication. The technicians will come onsite with the proper PPE equipment and bring everything they need for the job including tools and containers to remove debris and powerwashers that are made specifically for the application of descaling chemicals.

Our acid-cleaning treatment is a little more complex and as complexity grows, so does the size of the team, but that’s a less common job. We are OSHA-bound and can comply with customer-specific requirements to work safely in confined spaces.

“Certain states require regular cleaning of the cooling towers so facilities in those states need to have standing appointments with their water treatment partner.”

What to do Before Cleaning Your Cooling Towers

A professional water treatment partner can take care of all of the necessary steps to conduct before, during, and after cleaning your cooling towers. However, if you’re going to take on the job yourself, we recommend following the steps below prior to any kind of cleaning, whether mechanical or chemical.

- Isolate the tower or condenser from the system. Disengage electrical service using proper lock-out tag-out procedures to ensure fans and pumps cannot be activated.

- Close the water make-up, supply, and return valves to the system.

- Open the bottom drain of the tower.

- Remove the suction intake grates for cleaning, if possible.

- Use a pressure washer to clean the sidewalls and other exposed areas near the sump or basin.

- Have a squeegee, shovel, broom, or industrial vacuum available.

- Suit up in waterproof boots, PPE, and jumpsuit or coveralls.

- Push the mud and debris towards the drain and flush it down with the hose.

- When you are finished, reverse what was done in steps 1 – 4 prior to start-up or chemical cleaning.

Don’t Overlook Your Cooling Towers This Fall

As you prepare your entire facility for winter, don’t overlook your cooling towers. Make cleaning and disinfection part of your seasonal maintenance routine. Set a reminder on your phone and make observing your towers part of your digital work order/regular rounds.

Barkauskis advises: “Facility managers are the frontline of defense for their cooling towers. Whether you’re running year-round or not, you should at least inspect your towers on a regular basis so that in the event you need our help, we can clean your towers and get them ready for next season. An ounce of prevention now will save you time and money come next spring.”

Recent Blog Posts

Five Ways to Increase the Efficiency of Your Closed Loop System

Global 6K for Water