Your building’s steam boiler is potentially a million-dollar asset. Like any workhorse system in your facility, it needs care and attention if it’s going to run long and run happy. This includes proper care during the off-season, complete with monthly, quarterly, and annual check-ups. You wouldn’t just shove a thoroughbred into a stable after its last race, forget about it and expect it can leap back out next season in top form. The same is true for your steam boiler – it needs to be set up and prepared for any lengthy period of disuse.

Your building’s steam boiler is potentially a million-dollar asset. Like any workhorse system in your facility, it needs care and attention if it’s going to run long and run happy. This includes proper care during the off-season, complete with monthly, quarterly, and annual check-ups. You wouldn’t just shove a thoroughbred into a stable after its last race, forget about it and expect it can leap back out next season in top form. The same is true for your steam boiler – it needs to be set up and prepared for any lengthy period of disuse.

When your boiler does go idle — either for an extended off-season or during multiple, irregular periods throughout the year — it’s critical to put certain chemicals to sleep along with it. In the industry, we call this laying up your boiler, and ignoring this step can place a silent and costly toll on its insides. Lay a boiler up properly, and it will last longer, function better, and require fewer repairs. Over the lifespan of your equipment, this can easily add up to tens of thousands of dollars saved.

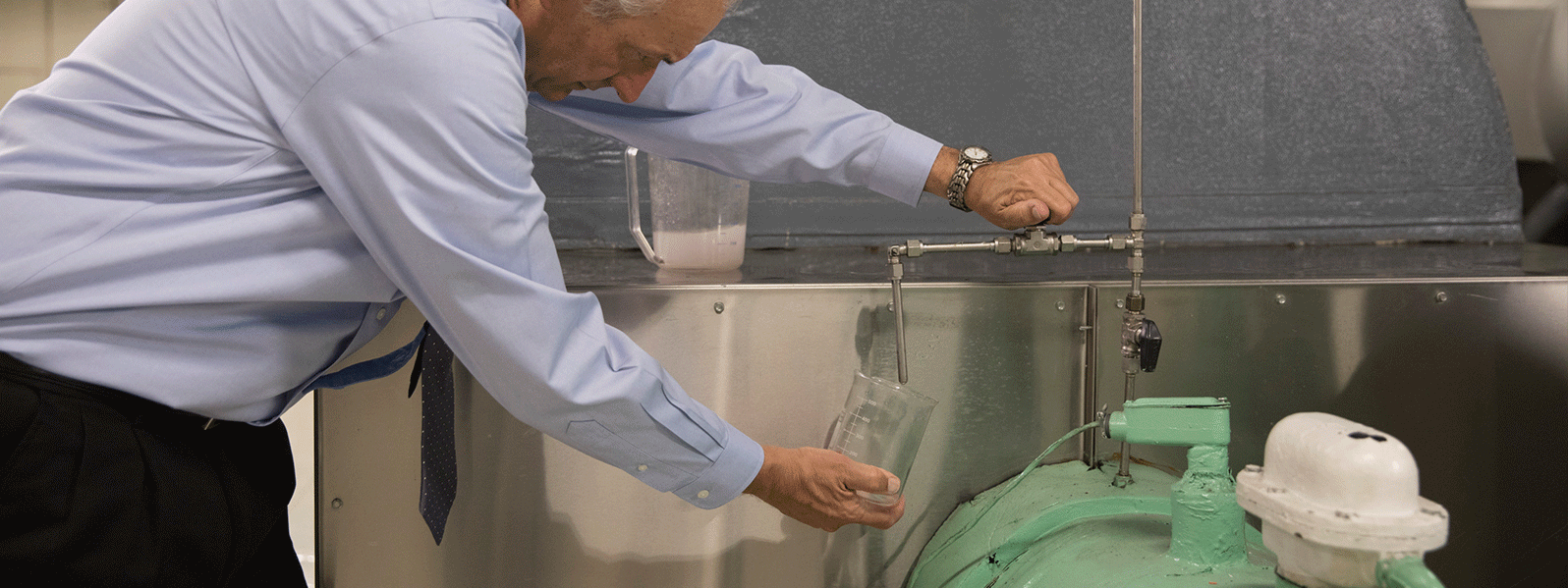

At HOH Water Technology, we’ve worked with clients all across the boiler care spectrum — from those who keep their 20-year-old boiler running as if they bought it yesterday to new clients whose first response is “we have a boiler?” Factoring in these different starting points, we’ve developed a handy list of steps you can take to ensure proper performance today and limited cost ramifications tomorrow.

Five Things You Need to Know When Laying Up Your Boiler

1. Lay Up Your Steam Boiler

The first tip is simple — do it!

In some ways, the results you get out of the layup process are more important than the standard operations done for traditional boiler water treatment. A proper layup can reduce corrosion throughout the year, stave off premature equipment failure, and delay the costly impact of an unscheduled downtime resulting from having to replace valves, tubes, or the entire system. It comes down to a simple equation: spend a little time and energy today versus paying a big-time bill and suffering headaches down the road.

2. Get Your Water Management Team in Place

As a building owner or operator, you’re responsible for countless tasks, but you can’t be everywhere at once. By delegating clear responsibility for boiler testing, maintenance, and the layup procedures, you’ll be able to ensure it’s done correctly and is given the priority status it requires. This is a reason to create a facility water management team.

On-site operators and engineers who monitor your systems, partnered with trusted water treatment professionals, can develop the necessary procedures to make layup preparation and execution part of your building’s normal maintenance strategy. And you should make layup more than a once-a-year job; there are plenty of steps you can take on a monthly or quarterly basis to avoid last-minute obstacles.

3. Observe Effective Steam Boiler Testing and Maintenance

Managing a steam boiler shouldn’t be a set-it-and-forget-it thing. Regular testing and maintenance allow your boiler to run smoothly when you need it most. As you test, watch for three key things:

- Measure oxygen scavenger levels. Oxygen is the big enemy you are fighting against in a steam boiler because it causes pitting corrosion.

- Monitor dispersant levels to keep solids from sticking to boiler surfaces.

- Watch the conductivity or total dissolved solids in the water. If you exceed the maximum allowance, you’ll start to have problems.

4. Wet or Dry Standby Procedures For Boilers— Choose Your Own Adventure

It’s time to lay up your boiler, but it’s not quite as simple as just doing it — you need to decide how to do it. You can go one of two routes: wet standby or dry standby.

- Wet standby means flooding the boiler with treated water

- Dry standby requires getting every drop of water out of the boiler and sealing it, often with a chemical desiccant

As water technology experts, it’s our duty and responsibility to provide insight on layup procedures and to help the customer make an informed decision that’s best for their facility. When deciding on your preferred layup method, consider conditions like:

- Boiler size and type

- Atmospheric, temperature, and location conditions while offline

- Duration of downtime

- Resources – materials and staff time – required to perform either the wet or dry layup

- Resources – materials and staff time – required to effectively monitor the boiler while offline

5. Get Professional Help with Preventative Maintenance of Your Steam Boiler

As a hands-on water treatment partner, HOH helps you get the most from your recirculating water every day – in your boiler and throughout your facility.

We provide all the treatments associated with wet or dry boiler layup. Your HOH representative can also provide technical expertise, testing equipment, and protocols for getting your boiler(s) into the proper layup condition as well as tips for implementing an appropriate testing and treatment strategy at your site all year long. You can rely on us for detailed instructions for on-site personnel, training, and other guidance.

Contact us for further assistance in laying up your boiler or to locate other helpful resources.

Recent Blog Posts

Five Ways to Increase the Efficiency of Your Closed Loop System

Global 6K for Water